When printing with an FDM 3D printer, such as a Makerbot or RepRap, you run into problems when printing objects that have large overhangs or bridges within your model. While SLS printers can use their extra material to make spacing for working mechanics within a print, that can be difficult to achieve in FDM prints. FDM printers can print support structures that are made with excess printing material, which can later be torn away, however this excess material must be on the outside or accessible within the print.

The solution to these problems is dissolvable suport material. Dissolvable support material can be printed to create a support structure within your model, but can later be removed by placing the print in a solution that removes that material. Many materials have been tried for use with hobby printers but without great results… Until now!

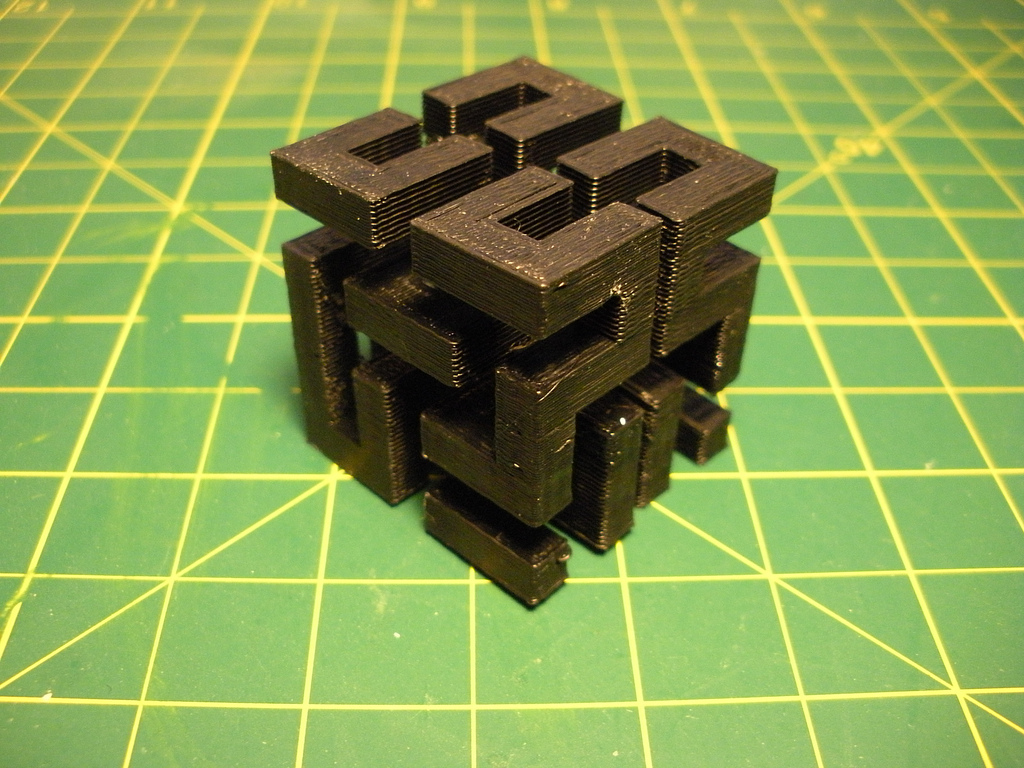

I have been working with HIPS (High Impact Polystyrene) plastic from Filaco, printing in combination with ABS. When printed as a tearaway support structure, HIPS can be easily torn from the ABS – leaving an even finish behind. The real power, though, comes from the ability to remove the HIPS support material by dissolving it away. HIPS is soluble in a chemical called Limonene. When a print is placed in a bath of Limonene, the HIPS portions are completely dissolved away – leaving behind just the ABS sections. This opens up the potential for moving parts and more complicated structures to be printed in one print instead of multiple.

I made my prints with a Makerbot Replicator 1 with two extruders. My process was simple.

- Both extruders set to 235C.

- Heated bed set to 115 (HIPS sticks really well at this temp and I did not have any curling issues).

- Wait for print to fully cool. HIPS stays very pliable until it’s cool and will bend when removing from your plate if not fully cooled.

- Place in a glass jar with enough limonene to cover for 24 hours, agitating as frequently as possible. Time may vary depending on the amount of material used, so monitor status every couple of hours.

- Remove your print and rinse in fresh water.

Your print will maintain a pungent smell of oranges – but hey, that’s not so bad, right?